Build your own signalling system

using our digital and internationally certified components

Strategic agreement with South Korean STraffic

We signed a strategic partnership with South Korean STraffic focused on control systems for railways and subways. The agreement includes collaboration on the South Korean market, which boasts more than 4,000 km of railway lines, including 625 km of high-speed tracks. Additionally, the Seoul Metropolitan Railway System, which serves the capital region, spans over 1,300 km of lines.

STraffic is a leading provider of innovative solutions for urban mobility, specializing in both railway and road infrastructure. Headquartered in Seongnam-si, South Korea, the company generated over 147 billion South Korean won (approximately USD 100 million) in revenue in 2023. STraffic has successfully completed critical infrastructure projects across 13 countries worldwide and is listed on the Seoul Stock Exchange.

We are pleased to present You our publication in the magazine "Signal + Draht" (eurailpress.de) on the ETCS L1 Limited Supervision. This is a solution that could increase the interoperability of European rail networks. Do you know that in 20 years ETCS has been introduced on only 3% of the European rail network? As indicated during the 2024 ERA ERTMS conference in Valenciennes, the only way to accelerate ETCS deployment is to change the approach. Instead of linear implementations, area implementations are needed. We invite you to download a copy!

Download Publication

Rail Solutions Asia

Our team visited the Rail Solutions Asia 2024 Show in Kuala Lumpur, Malaysia. We presented our certified balises and a unic programming tool. Thanks to the automated and robotic production line we are able to deliver quality ETCS components at highest quality, lowest price and really fast. Stay tuned for the next journeys of our team and presentations of our solutions. Would you like to schedule a demo in your city? Please leave us a note!

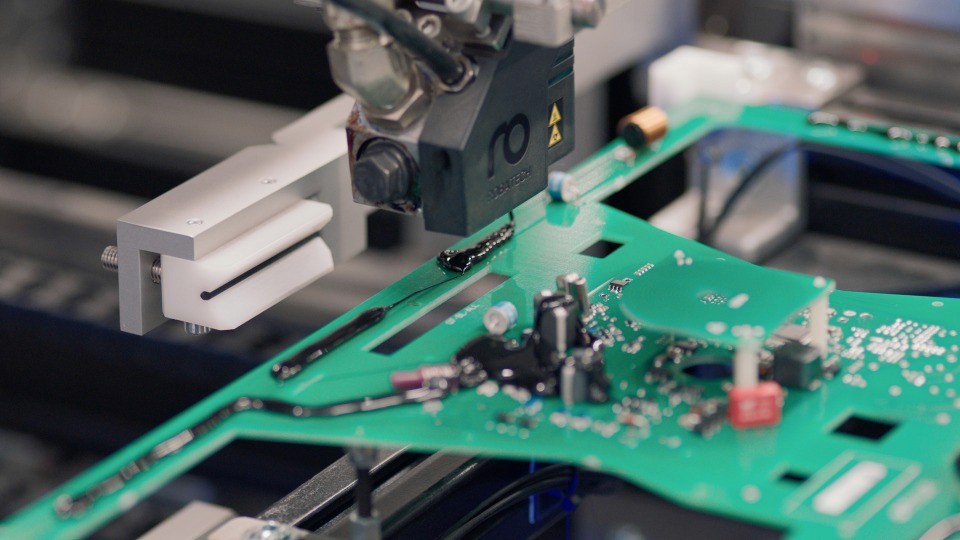

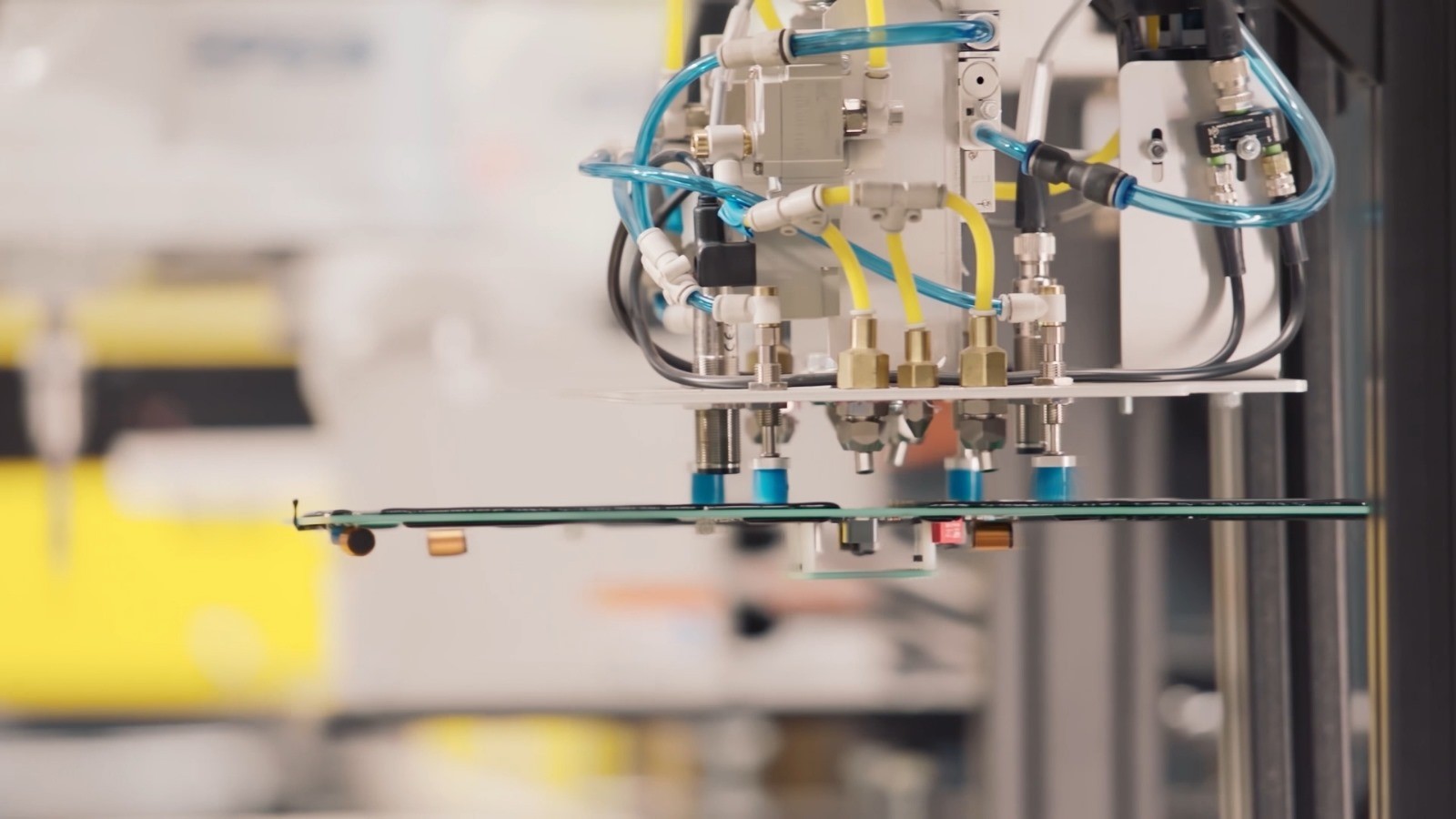

Production line

70 per day and 17,000 Eurobalises per year - this is the production capacity of the new, fully automated line launched in Warsaw. Eurobalises, electronic devices designed by Kombud engineers in the ETCS standard, transmit a telegram to a moving train in a fraction of a second.

The production line moves at a rate of 6 minutes per stage. This time is necessary to program the balise, calibrate the antennas and fill the housing with a special resin, the composition of which is a company secret. The Poka-Yoke methodology used in the construction of the housing ensures the correct positioning of the electronic card and the perfect positioning of the antenna, the center of which must be placed in the track with an accuracy of several millimeters.

Railways

KDP

High-Speed

Railways

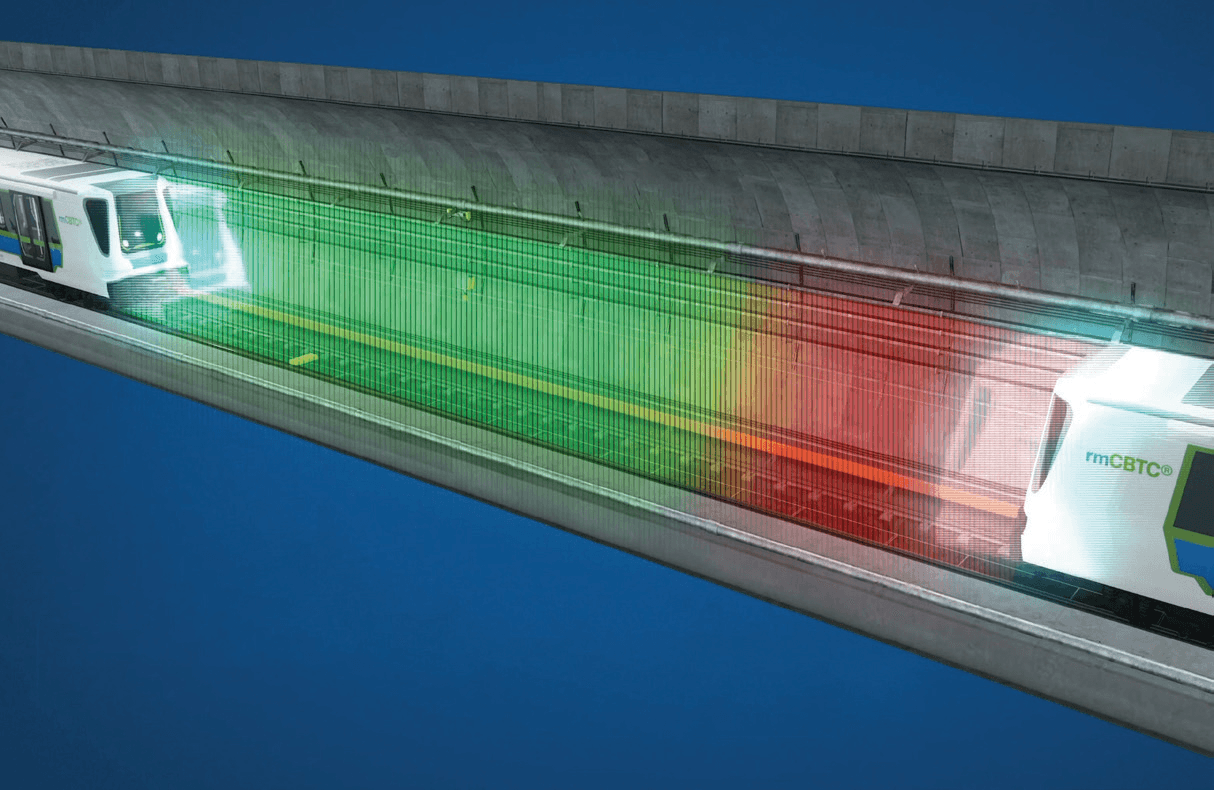

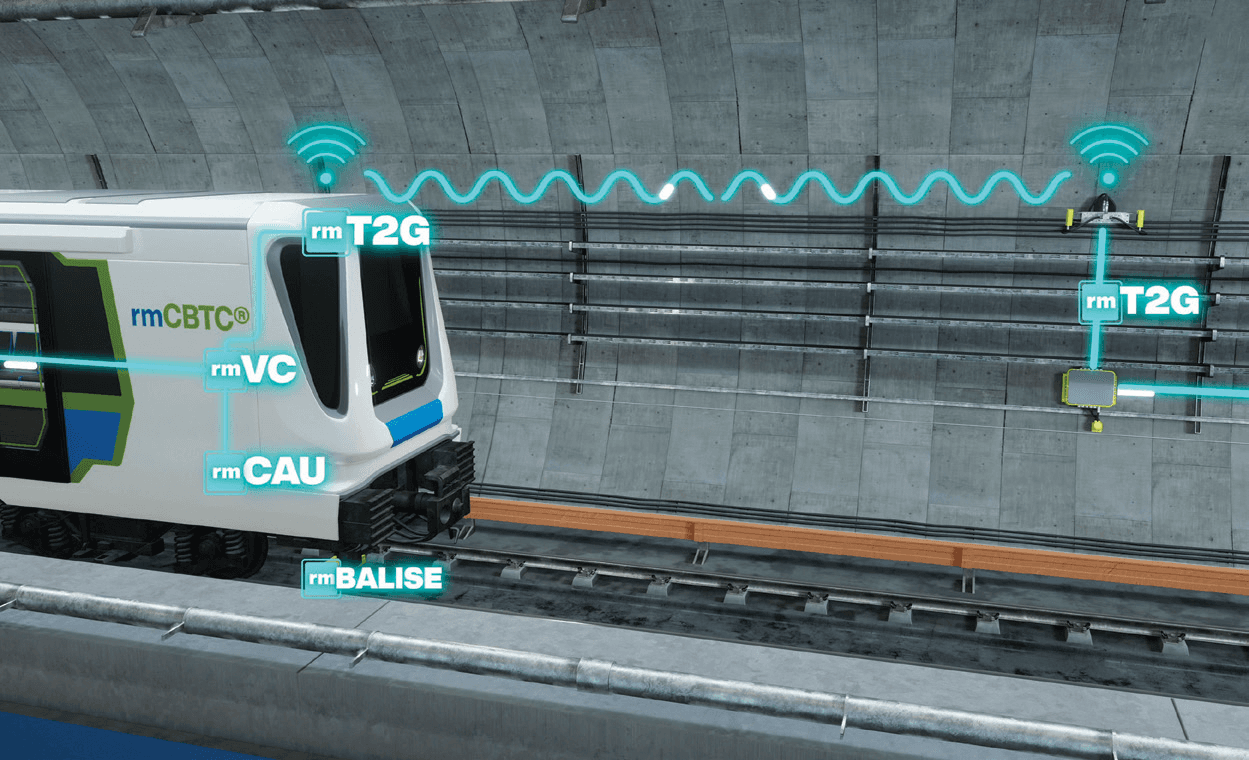

Metro & CBTC

Metropolitan

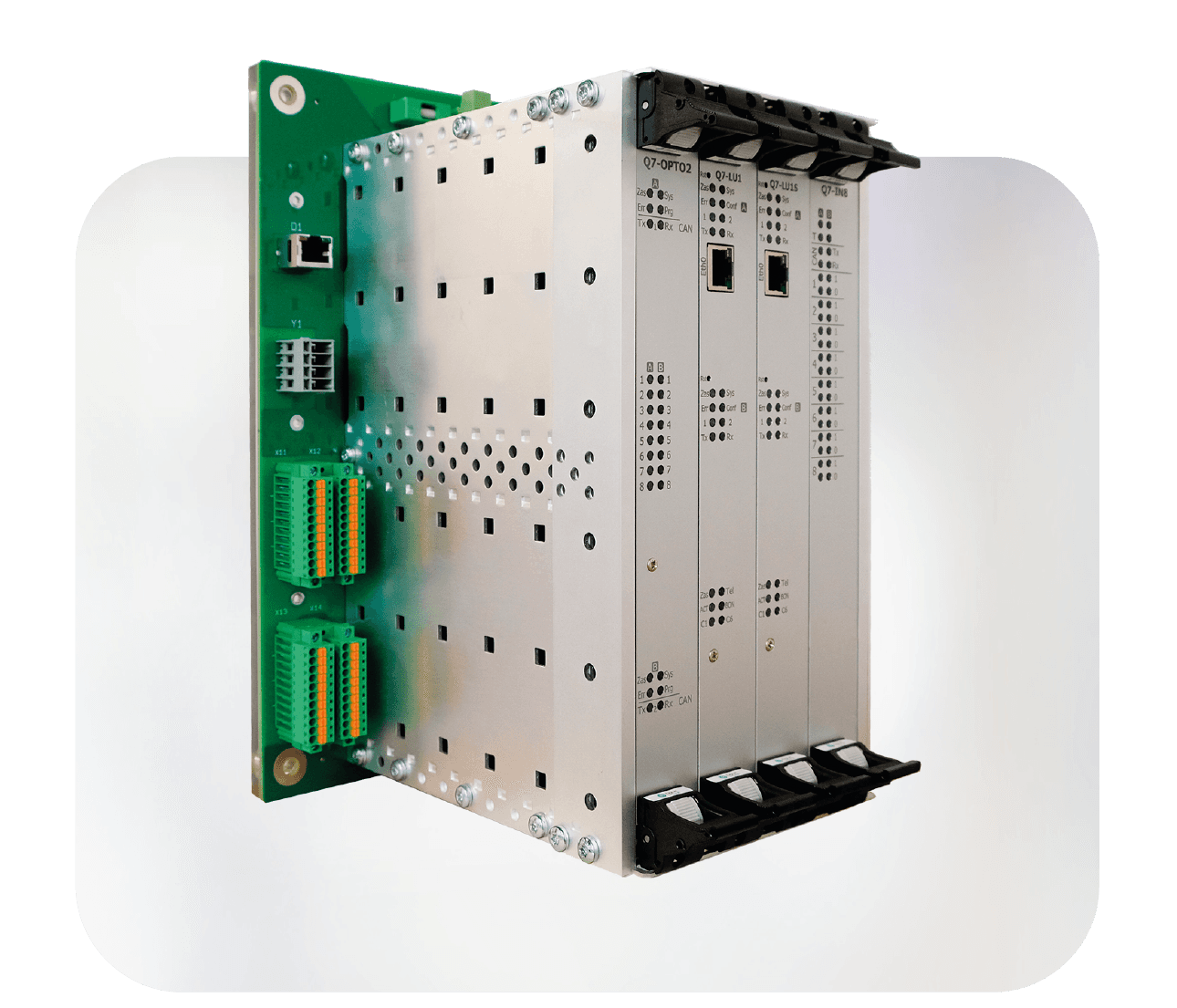

LEU Coder

Sophisticated on-site diagnostics

Built-in, centralized LEU diagnostics

Modular design allowing for expansion of the system or replacement of components

Built-in ability to configure and parameterize input circuits

Flexibility in defining the electrical parameters of image detection on the semaphore

Flexibility in defining the electrical parameters of image detection on the semaphore

Interoperability compliance – certified for TSI Control-Command and Signalling (TSI CCS)

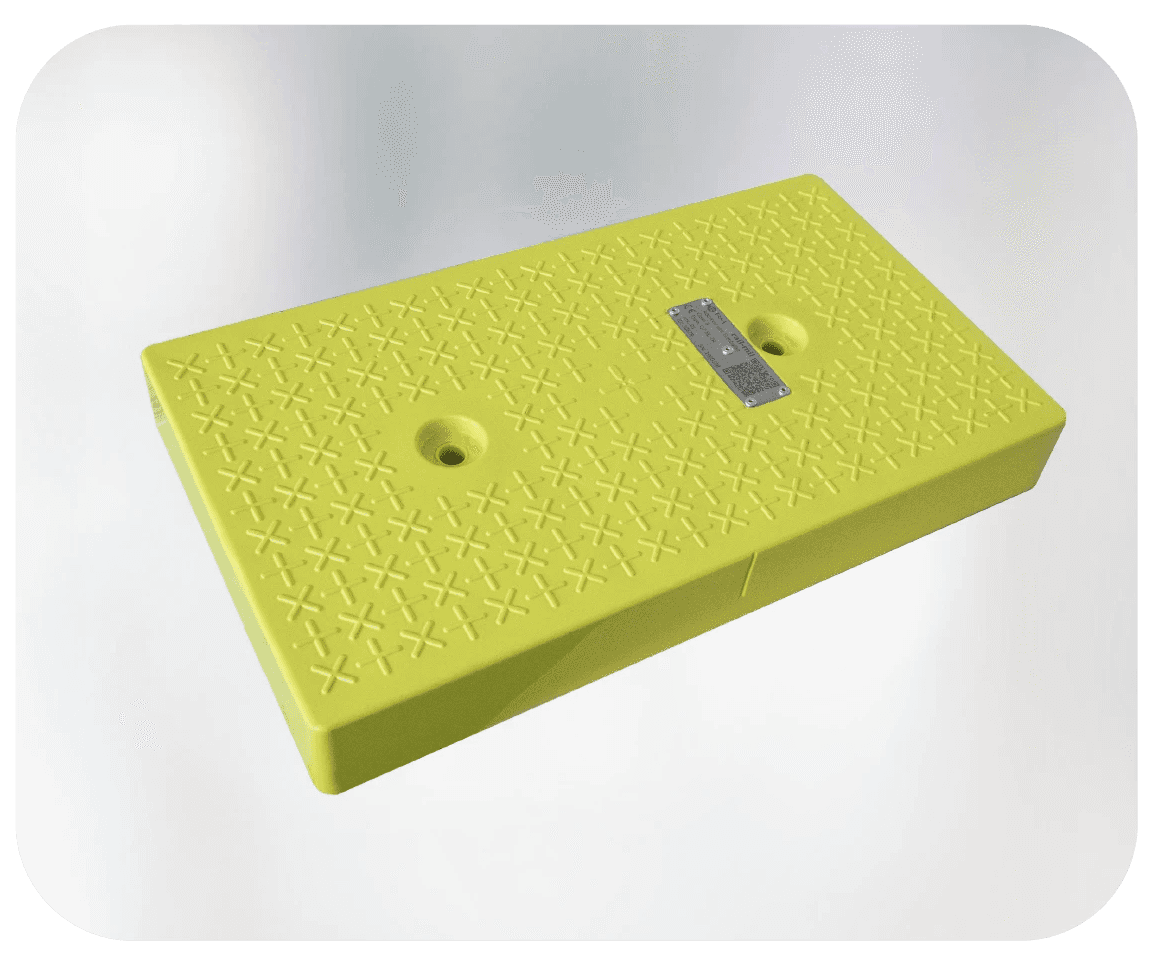

Balises (fixed and controlled)

The on/off function for balises enables efficient and safe installation works on active lines

Possibility to identify the author, content and time of any changes in telegrams thanks to specialized software

Scalability – a robotic production line with high efficiency and low unit cost

Ergonomics of the balises increasing safety and reducing the cost of installation work

Possibility of delivering fixed and controlled balises

Standard installation and optionally the availability of a convenient rail mounting.

Interoperability compliance – certified for TSI Control-Command and Signalling (TSI CCS)

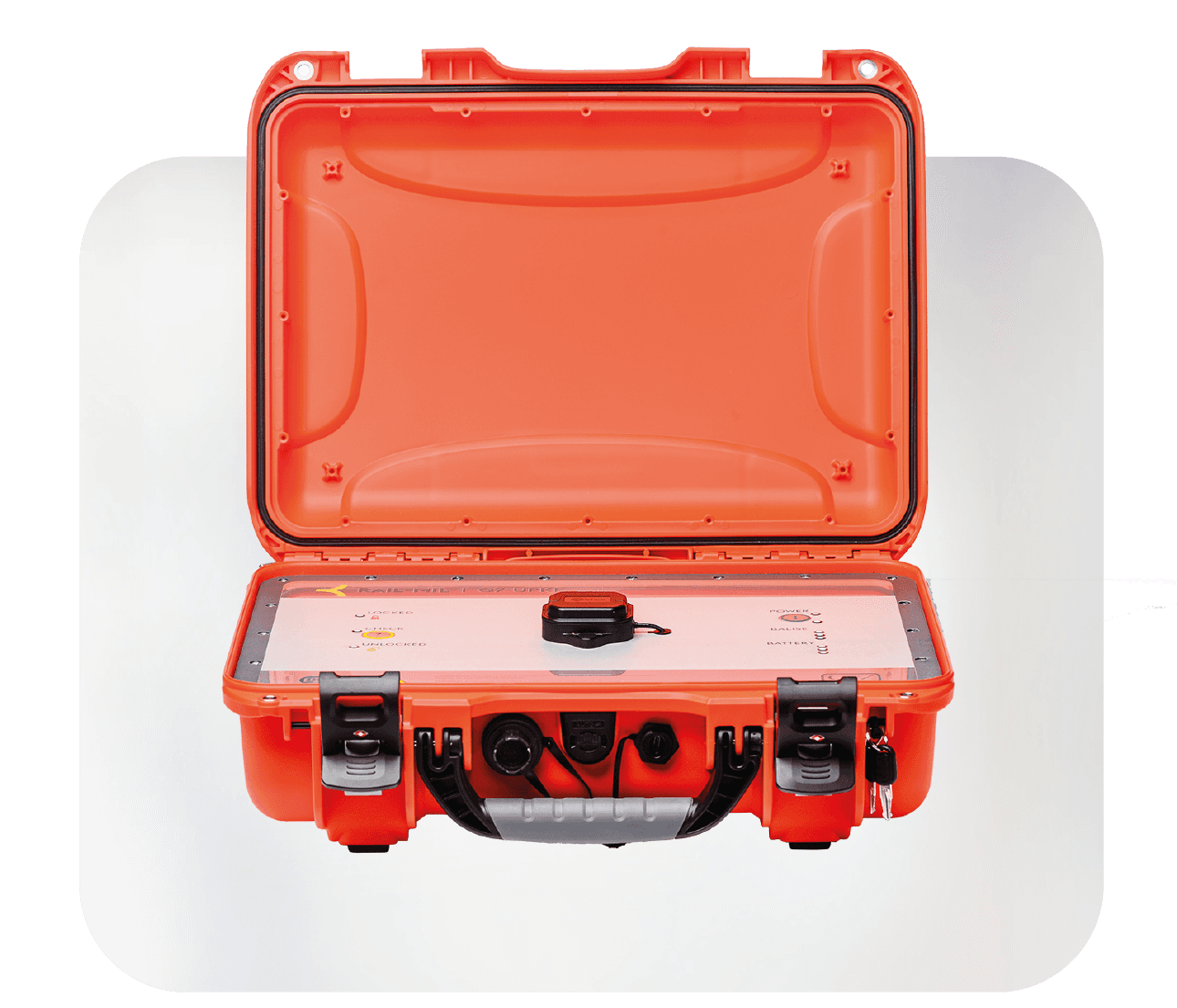

Possibility to lock and unlock the balise from the programming tool via the air gap, without cables

Handy case providing good protection against weather conditions (IP 65)

Rechargeable battery with a runtime of up to 20 hours.

Wi-Fi interface for diagnostic and programming from PC

GPS for data collection and time synchronization

Increased cybersecurity via programable, registered access keys

METRO STATIONS

0

+

0

+

STATION INTERLOCKING SYSTEMS

0

+

digital line block

systems

0

+

level crossing

systems

+